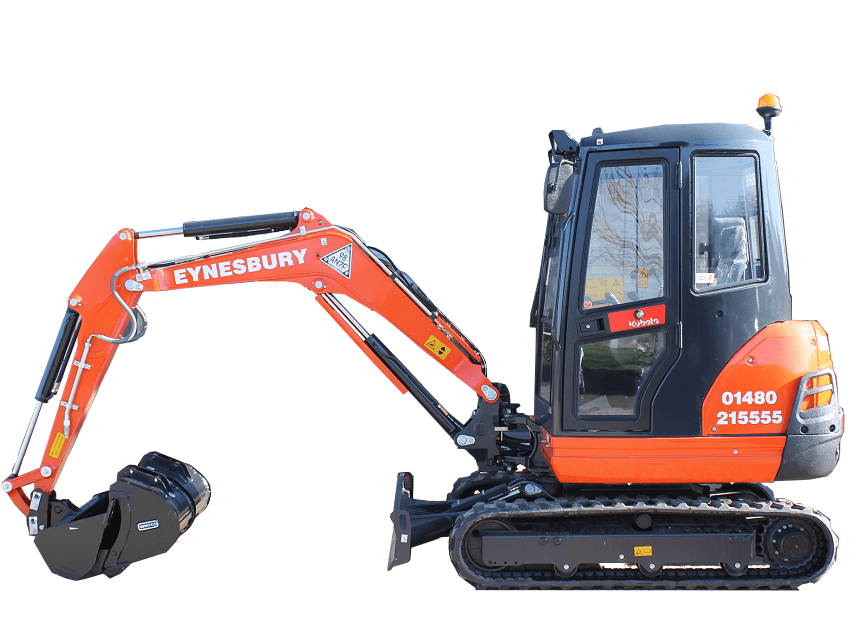

Compact - Mini Excavator

A tracked or wheeled machine with an operational weight of 0.7 to 8.5 tonnes is referred to as a micro or mini excavator. It often has an independent boom swing in addition to a standard backfill blade.

Since hydraulic fluid is carried throughout the entire machine during all movements and operations, hydraulic excavators differ greatly from conventional construction equipment in this regard. On the little excavator, hydraulic fluid passing across hydraulic cylinders activates the work group and blade. The excavator's slew (rotation) and travel operations are also propelled by hydraulic motors that are fueled by hydraulic fluid.

What Sizes Do Micro And Mini Diggers Come In?

There are many different sizes of micro and mini digger; below, we've included the most popular sizes, along with a description and some of their main uses.

0.8 Tonne Micro Digger - Excavator

General Information

These devices easily fit through a regular 760mm fence or doorway, making them perfect for use in backyards or other locations with restricted access. The roll bar may be lowered to provide access in low-lying places, and its expanding track system boosts stability while it's in operation. This machine can be used for a variety of landscaping duties as well as other modest tasks because of its straightforward controls.

Features

Adjustable track gauge

1 lever operation

The front end hydraulic piping is run within the boom, and the best protection is provided by a boom cylinder that is mounted on top of it.

Folding ROPS may fit through doors and are simple to transport.

Superior results

Extremely compact and reliable when there is a need for a lot of work and there is little room.

1 Tonne Mini Excavator - Digger

Information

xcavators weighing one tonne are robust, flexible, and long-lasting. These excavators are ideal for trench digging, hole-breaking, garbage collection, and mine excavation. The sleek and portable design of the 1-ton digger allows it to fit into even the smallest spaces. Even in densely populated settings, it is safe to use due to its comfort and silence.

Features

with a four to twelve inch back overhang

a retractable undercarriage between 28 and 29.5 inches

6 feet is the maximum digging depth, and 7 feet, 8 inches is the maximum digging height.

Mechanical handler with a simple design, high-precision pilot joystick, and EPA Tier 5 and emission standard compliance.

a very adaptable side-to-side swing boom

a ROPS bar for the operator's protection

1.5 Tonne Mini Excavator - Digger

Information

If access is not an issue, the 1.5 tonne mini excavator is the most common size for compact settings. To increase stability when digging and tracking, the digger widens its tracks. We do not propose utilising this machine as a crane and it can accept a breaker attachment but not an auger attachment (breaker price is additional).

Features

105cm wide

23.6cm in height

Weight with fuel & buckets, is 1.8 tonnes.

23.9cm of digging depth

4035mm length

Dump height max - 2705mm

Tyre tracks

Widening track spacing

A glazed cab

Blade for a bulldozer + extensions

Swinging off-set boom

differing bucket sizes

2 Tonne Mini Excavator - Digger

Description

The 2 tonne diggers can be used in most situations thanks to their fully covered cab and extra feature of hydraulically movable tracks for enhanced support and agility. The effect of this is that the digger is 100mm thinner than a 1.5 tonne digger with the tracks closed.

Features

Over the 1.6, the 2 tonne digger offers a number of advantages (based around longer reach and stability)

considerably broader blade (extension removed for narrow access)

There is a longer track frame.

longer blade for a dozer.

greater weight

3 Tonne Mini Excavator - Digger

Description

The largest digging depth and reach of any excavator in its weight class are provided by this 3-ton compact digger. It can only be adjusted to a width of 1.5 metres despite having a long reach and a strong digging motion.

Even though it can narrow down to just 1.5m wide, the 3 tonne compact digger succeeds where other small diggers in its class fall short by offering operator comfort. Additionally, it features a roomy cabin and is exceptionally sturdy on uneven terrain. When necessary, it also offers a lot of lift force.

Features

The tracks may be changed up to 1500mm and offer great performance and stability.

diesel engine with four cylinders and a 27.5 PS power rating.

This sort of small excavator has a maximum depth of about 3 metres (2870mm).

powerful lifting and digging abilities.

Strong and spacious cabin for the operator's safety and comfort.

Excavator Parts And Attachments

Excavators can be adjusted to match the requirements of a particular job by switching out the attachments. Buckets, augers, breakers, thumbs, and couplers are a few examples of typical hydraulic attachments.

Excavator Bucket

The most popular excavator attachment is a bucket. They are perfect for scooping and excavating because to their steel construction and teeth-like edges. The most typical buckets are those used for ditching and grading stones (sometimes referred to as "ditching buckets") (the trenching bucket). It's vital to consider the quality of the soil and any prospective attachments, like couplers, when choosing the sort of bucket to buy or rent.

Mini Excavator Auger

A tool used to drill into the ground is an auger. They can swiftly and effectively dig deep holes since they are hydraulically powered. Augers may dig up to 32 feet and range in size from 4 inches to 50 inches.

Mini Excavator Breaker

Breakers, which resemble a larger jackhammer, can easily penetrate concrete, stone, and other hard materials.

Mini Excavator Thumb

For objects that are too big for a bucket, like a tree trunk or concrete slab, thumbs work nicely. It is simple to put them on and take them off.

Mini Excavator Couplers

Couplers facilitate and speed up the exchange of attachments. An attachment coupler can help you save time, money, and resources like personnel if your profession necessitates frequent attachment adjustments.

How to Use a Mini-Excavator

Nowadays, everyone is seeking for faster ways to get things done. Mini excavators could provide comfort for contractors and homeowners. These tools are extremely adaptable, allowing you to use them for almost any kind of construction activity, from hammering concrete to digging holes for landscaping. These adaptable, user-friendly devices are important development aids, especially in urban environments where space constraints necessitate more compact, lightweight equipment.

What can A Mini Digger Do?

For pipe digging and demolition tasks, add a hydraulic hammer.

At a busy intersection, dig out a curb or walkway without blocking traffic.

To load brush and sort recyclables, attach a thumb and an earth auger.

Use for a variety of backyard tasks, such as digging sewage or electrical conduit.

For demolition and recycling, concrete should be broken up with a hammer attachment.

Use 12- to 24-inch-sized buckets to dig holes for landscaping projects.

strip mall interior finishing, plumbing installation, and concrete removal with the least amount of disruption to neighbouring companies.

Older buildings are easily dismantled and redesigned on several levels because to their low buoyancy, which allows for improvements.

The two pieces of equipment, when used with a skid-steer, could occasionally be less expensive than a larger backhoe. They are also capable of managing two projects at once.

To collect various sorts of digging and soil, many types of buckets can be utilised. For digging footings, for instance, use a 24-inch bucket. To dig up utility lines, use a 12- or 18-inch bucket. To drain water and loose dirt from damp soil, use a 36-inch drainage bucket.

What Benefits Come With Using A Mini Digger?

Despite being little, micro excavators feel like large machines. These tools are perfect for huge excavator operators who dislike bouncing backhoes. Mini excavators offer both professionals and homeowners a number of benefits. These devices:

Enter tiny, confined spaces; some fit via yard gates.

Almost anyone can climb onboard and learn how to operate it in a few minutes because they are designed to operate similarly to larger excavators.

Include a quick-coupler connection that will make changing any attachment that is mounted on a dipper simple.

They are far quieter than large gear when travelling over concrete and other hard surfaces.

There should be easy-to-use controls provided.

have lightweight rubber wheels that are easy to manoeuvre through tight places without causing any damage to the ground.

They can be transported using the power of the pickup truck and are small enough to fit on pull-behind trailers. Some even fit in a pickup bed that has been expanded.

Utilize a range of accessories.

have a 360-degree swing arc so that more units, like a dump truck, can be placed wherever they are needed. The excavator can then be turned to position the load where it is required. Usually, the height of the dump is not a limiting factor.

Steel rails should be avoided since they will grind and scrape the ground.

Have non-slip rubber treads so you can carry the machine after you've loaded it.

Because they don't require specific highway carrying permits or business driver's licences, companies can reduce their paperwork.

Using A Mini Excavator

Read the instruction handbook for the tiny digger and any warning labels that may be connected to it. Next, inspect the gadget for any broken or missing parts. Keep an eye out for any potential dangers including leaks, frayed cables, track issues, or other challenges.

Make sure the plant has enough fuel to complete the task. Keep in mind that there are new regulations for utilising red and white diesel (rebate fuel). Make that your excavator is loaded in accordance with the current regulations. The usage of gasoline that has been rebated is restricted to a small number of industries, such as farming, horticulture, and agriculture, as well as government tasks like gritting icy roadways. Unfortunately, DIY and building are of low quality. Once the fire extinguisher is located, check the engine's levels of coolant and lubrication. You may now ascend to the command console.

On the left side of the tiny excavator are controls and an armrest. It is typically raised and moved out of the door's path. The armrest can be locked in place by pulling it downward. Check the driver's console next, then buckle up your seatbelt firmly. Find the ignition switch and all of the available gauges and controls. The ignition switch is typically located either above or to the right.

There are many pedals, levers, and joysticks inside the excavator's cab. The rotation of the left and right cabs, the boom, and the bucket is managed by the joysticks. The front blade, throttle, and driving tracks are controlled by levers. The high-speed option and the bucket's pivoting are controlled by the pedals (if applicable). Move each control while the digger is operating to get a sense of how it responds. The machine responds immediately to any control movement. It is therefore best to become familiar with their motions before beginning work.

Learn the basics of the device.

Look at the gadget

Verify the fuel level, etc.

Get familiar with the controls on the console.

Is It Simple To Operate A Mini Excavator?

Once you've become used to the controls and the machine's movements, mini diggers are actually rather simple to use. They are versatile and flexible.

The item's size, complexity, and number of features all have an impact on how simple or difficult it is to use. The standard attachments for mini and micro diggers are the front shovel, boom, and swinging bucket, giving the user strong equipment in a compact size. Larger excavators are more difficult to operate and require qualified heavy equipment operators.

Why Use A smaller Mini Excavator?

Mini diggers are compact and useful for a variety of professional and do-it-yourself operations. Here are just a few advantages that make equipment so alluring:

Choice: A variety of mini digger sizes and types are available. Depending on how you intend to use it and the scope of the project, select the best alternative. Take into account the area that can be used on the job site for safely keeping the little digger.

Due to their small size, they are preferred by companies who run many sites. They are basically moved from one location to another on trailers. Homeowners can easily borrow the little excavator, which is the ideal size for do-it-yourself projects.

Less pollution occurs since the areas are limited. Topsoil and other outdoor surfaces are less likely to be harmed by the smaller tracks and other attachable equipment.

What Are Some Uses For A Mini Digger?

The mini digger can be used for any project due to its small size. Utilize these to choose the best Mini excavator for the job at hand.

Smaller excavators are portable and simple to manoeuvre in limited spaces, making them ideal for digging holes. They normally include a variety of accessories and the user manuals when they are rented out. You'll be able to choose the best attachment for the proposed excavation or hole thanks to this information.

Micro diggers are excellent for digging while planting trees and plants in your garden. They are perfect for setting up ground irrigation on a site when properly prepared. They rarely disturb the soil or plants because of their small weight. They are essential when adding new garden elements like swimming pools, ponds, and hot tubs. The little digger can move large machinery and level the ground for the project.

Mini diggers are ideal for tearing down tiny, deteriorated yard buildings like sheds or fences.

What Controls Does a Mini-Digger Have?

The main boom is brought down with the right hand.

Right hand back: main boom up.

Main boom up, right hand back.

Using your right hand, curl out the bucket (dump)

Swing the left hand to the left.

Swing with the left hand to the right.

With your left hand, step forward and stick boom (dipper) away.

Stick boom (dipper) close from the back using the left hand.

The ISO pattern is the most typical control configuration for an excavator. The SAE controls are the most used pattern in America. They are similar but distinct since the main boom and stick boom's controls are placed in different places. For instance, the primary boom can be raised and lowered by moving the left joystick forward and backward.

Do Mini Or Micro Excavators - Diggers Need A License To Operate?

Any private property, job site, or access road may be used by an unlicensed driver to operate a mini-digger. Therefore, you can dig on your private property without obtaining the necessary permits. The only need is that you have a valid licence in order to drive any size of digger on a public road.

You must be qualified to work in public areas or by the side of the road. You can operate any size rotating-base digging machine in any of these places as a 360 excavator operator.

You must enrol in lessons at a training provider to obtain a current Construction Plant Competence Scheme (CPCS) card in order to operate a 360 excavator. To work on a construction site, you also need a Construction Skills Certification Scheme (CSCS) card.

Tips For Safe Mini Digger Operation

Make sure the detachable roll cage is firmly fastened before using the digger if it lacks a cab. A cage can shield people from severe danger if the piece of equipment tips over.

Driving should only be done on smooth, level terrain with the wheels or tracks parallel to the ground. Stability is required to dig a trench that is level.

Even if the bucket is empty, avoid swinging it over someone, especially if they are inside a piece of plant equipment or a portable toilet. There's no need to ever put anyone else in danger because anything can happen.

To prevent hitting the tracks, wheels, or front blade with the bucket, exercise caution when moving the arm in close proximity to the cab. owing to the pneumatic system's durability and the potential for costly bucket breakage.

When excavating, try to keep the track or wheels away from the trench's edge. Here, especially if the soil and ground are soft, they may be more fragile and prone to crumbling.

Is It Possible To Rent A Small Digger Or Excavator?

Numerous businesses rent out different types of small (or compact) excavators. Mini excavators can be utilised for a variety of tasks on the job site, and renting equipment is far less expensive than buying it.

Equipment must be used on site for at least 70% of the time in order to be cost-effective. Additionally, the owner is responsible for covering the costs of maintenance, inspection, and insurance, and equipment loses value over time. You just need to think about rental and fuel costs when using equipment that has been rented from a reliable company.

Is A Mini Excavator Operation License Required?

Any size of excavator must be operated on a public road with a valid driver's licence. On private job sites or access roads, however, a licence is not required. The 2011 Work Health & Safety Act does away with the need for excavator operators to be certified.

Excavator operators need to be knowledgeable about all instructions and information available, as well as competent and skilled. Legally, operator competency is ultimately the responsibility of the Person Conducting a Business or Undertaking (PCBU). It is necessary to inform them about authorised users and their familiarity with proper usage, restrictions, safety, and maintenance.

Are LOLER Inspections Required for Mini Diggers?

Excavators are frequently used for both lifting and excavation on building projects. All lifting equipment should undergo routine Lifting Operations and Lifting Equipment Regulations (LOLER) inspections.

A "competent person" who has experience examining lifting equipment should conduct these inspections, and they must create a written report of their findings. Under Section 6 of the Health and Safety at Work Act, hire firms are considered suppliers and are in charge of providing secure equipment.

This calls for thorough inspections, equipment testing before use, and regular inspections. It is feasible to draw up a written agreement to transfer this to the hiring party for excessively extended hire terms. The user is typically alone in charge of doing daily and initial safety evaluations.

How Deep Can A Mini Excavator Dig Into The Earth?

Of course, the size of the model being used is an issue. The TB260 6 tonne can dig down to a depth of 3.895 metres, as opposed to the limited 1.755 metres of the Takeuchi TB210R. The reach needed will vary depending on the particular project, but it is preferable to plan on going a little deeper than necessary. This accounts for any workplace challenges that demand increased depth without the use of additional instruments. The type of ground should be taken into account while choosing an excavator.

For instance, deeper footings will be required if construction is to take place on soft ground. Greater bucket reach and digging effort are required in clay-rich, hard soil. Care must be taken when excavating close to utility wires and subterranean pipes to prevent damage (such as broadband cables and electrical supplies). Mini excavators are perfect in this situation due to their relatively shallow digging depth and smaller bucket width.

How Much Weight Can A Mini Digger Lift?

Contrary to their moniker as "diggers," excavators are frequently used for lifting and removing impediments. Even when excavating, garbage needs to be shifted or pushed out of the way. The trash in the bucket will be substantially heavier with concrete, hardcore, or other materials than it would be with dirt or other comparable ones. Before hiring, it is advisable to evaluate the lifting capacity because, like digging depth, it rises with the size of the excavator.

The lifting capacity of an excavator depends on its hydraulic and tipping capacities. The hydraulic capacity of the machine determines the heaviest load it can raise before stalling. An excavator's tipping capacity is the weight of the load that it can lift and possibly tumble.

The Operation and Maintenance guide contains lift charts based on factory testing, and they are prominently displayed on the machine. It is typically visible to the operator because it is in the cab or canopy. It should be understood that lift capacities are computed for usage on level, even surfaces and must be adjusted when used on hills or other uneven terrain.

On the website of the rental company, the specifications should include information on the excavator's lifting capacity. If you're not sure, check with the business to see if you have the required tools. Care must be taken during lifting because any accident could have serious repercussions for the operator and close workers.

How Heavy Is A Mini Excavator?

Tiny diggers can weigh as low as one tonne, whereas mini excavators are typically described as machinery that weighs less than 7 tonnes.

One of their major benefits is that they are made of lightweight materials, allowing for use without damaging delicate or sensitive surfaces. Additionally, the majority of versions include expanding rubber tracks that aid in dispersing the weight of the equipment. For indoor work or on finished surfaces, they are perfect.

The margins of flooring or pavement are more likely to be damaged by larger versions because to their heavier weight and metal rails. Mini excavators are readily carried by truck or trailer due of their light weight.

Manufacturers Of Mini Diggers We Offer

We provide mini excavators from JCB, Bobcat, Kubota, and Caterpillar.

Bobcat Mini Diggers We Supply

Shuvs Digger Hire Buckinghamshire Copyright© 2022 All Rights Reserved